Phased array ultrasonics (PA)

Phased array ultrasonics (PA) is an advanced method of ultrasonic testing that has applications in medical imaging and industrial nondestructive testing. Common applications are to noninvasively examine the heart or to find flaws in manufactured materials such as welds. Single-element (non-phased array) probes, known technically as monolithic probes, emit a beam in a fixed direction. To test or interrogate a large volume of material, a conventional probe must be physically scanned (moved or turned) to sweep the beam through the area of interest. In contrast, the beam from a phased array probe can be focused and swept electronically without moving the probe. The beam is controllable because a phased array probe is made up of multiple small elements, each of which can be pulsed individually at a computer-calculated timing. The term phased refers to the timing, and the term array refers to the multiple elements. Phased array ultrasonic testing is based on principles of wave physics, which also have applications in fields such as optics and electromagnetic antennae.

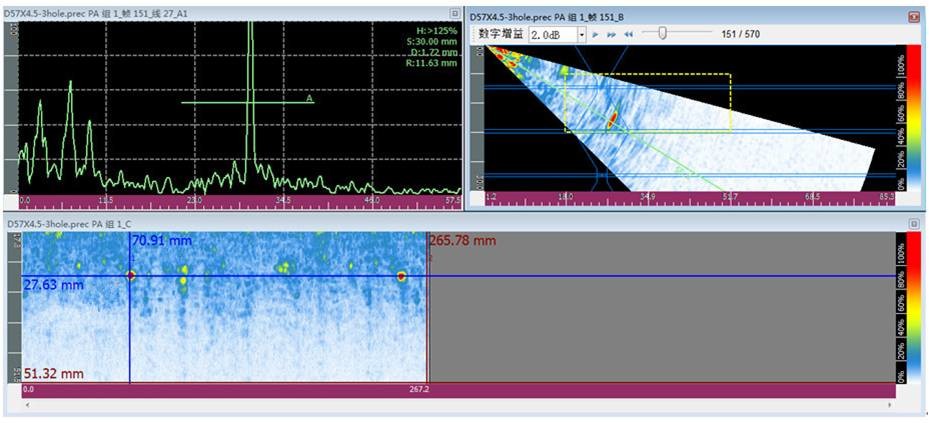

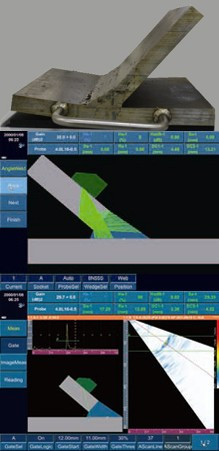

Portable PAUT and TOFD Flaw Detector SyncScan

PA Inspection Advantages over RT for Small Pipes Inspection

Nowdays,most pipeline inspections are performanced by RT. But to replace it with Phased Array (PA), it got many advantages:

- PA is faster. To use RT for small pipes inspection, it takes about 10 minutes to inspect one welding defect. For PA, it takes only 1 minute.

2. PA inspection is not restricted to circumstance.

For RT, you can only do it in the evening, and PA inspection can be performanced 24 hours each day.

According to our statistics, for one evening, by using RT inspection, you can do more than 10 welding defects testing. But for PA, you can do over 100 welding defects in one day.

So this can greatly improve the inspection effeciency.

3. PA inspection result can be stored, edited, reports generated, movies displayed in the computer, while RT inspection result can only be stored in films, which means you need to buy films, and not easy to store.

For PA inspection storage, it is not restricted to storage capacity, and all the data can be stored by USB disk, or transfered by Ethernet ports.

PA Inspection Advantages over RT for Small Pipes Inspection

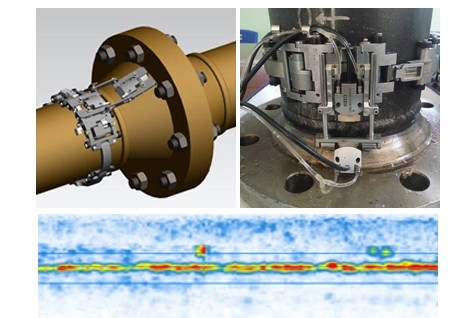

For PA, it can adjust and set scan mode to inspect different welding parts, especially for some difficult welding structures like angle weld, TKY joints, flange weld and elbow weld.

Now with the PA flaw detector SyncScan from SIUI, it has different build-in software to meeting different difficult welding inspection solution, like Angle Weld Software:

PA Inspection Advantages over RT for Small Pipes Inspection

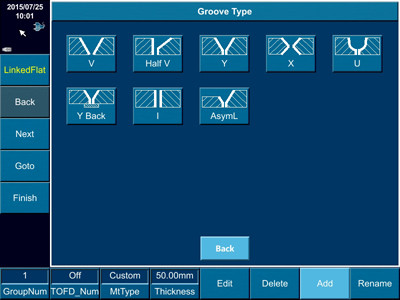

Flat Weld Solution, eight types of weld groove including V, Half V, Y,X,U,I, Y with backing, Asymmetric Welds are available in the software:

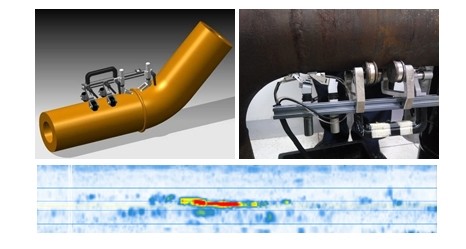

Pipes ELBOW WELD and FLANGE WELD Solution on pipes OD≥168mm: